Responsibility › Environment & natural resources

Respecting the natural environment means understanding its limits and how our activities can have an impact.

We recognise that our businesses use natural resources, and create emissions and waste. We aim to be responsible stewards of the environment by minimising any negative impacts. Our approach towards the environment is governed by the AB Mauri Environment Policy.

View AB Mauri Environment Policy

SUPPORTING

Water

Water is vital to our business. In our yeast plants it is the medium in which yeast cells live, grow, and reproduce. Throughout our operations we also use it to keep our equipment and facilities clean and efficient.

Wherever we work we aim to be efficient with water and return it safely to the environment after use. By doing so we aim to support our strategy of operating at our sites long term through minimising our impact on the water security of neighbouring communities.

Here is a video of our Head of Manufacturing Oscar Touceda, discussing the importance of water to our business, and how we return water to the environment safely and sustainably.

Our water strategy, designed and implemented by our global water champions, focuses on sharing best practice in four "R"s:

Reduce water use where appropriate,

Reuse water directly where appropriate,

Recycle treated water back into our operations,

Return treated water safely to the environment to a standard that meets or exceeds local regulations.

Effective treatment can also create useful by-products – see Waste and Circularity section below

Since 2010 AB Mauri has invested over

$120 million

in water treatment CapEx , with over $50m more in the pipeline

Anaerobic treatment facility at AB Mauri's plant in Hull, UK

Water Intensity

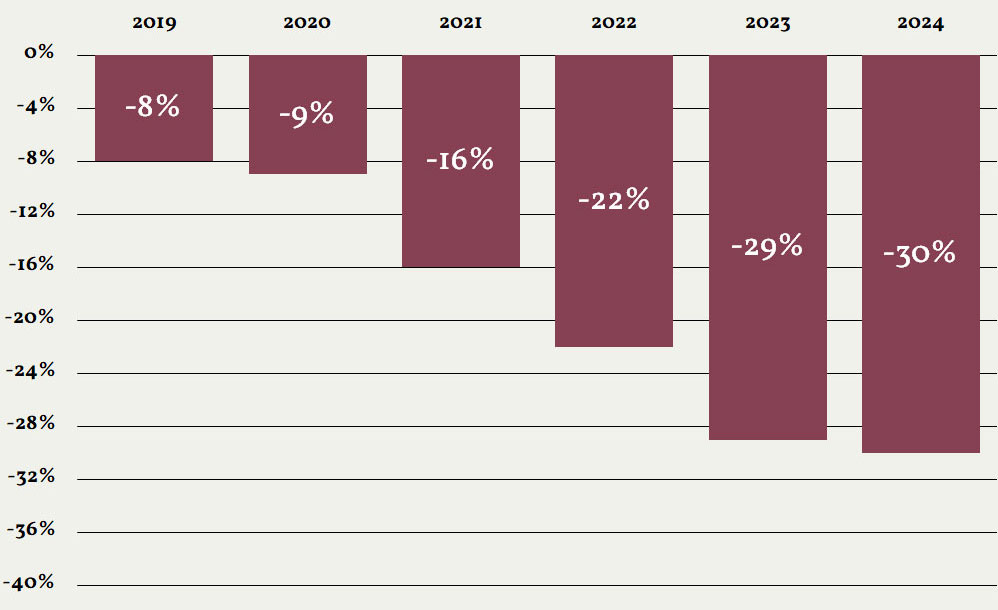

Showing the yearly % change in Water Intensity*

At AB Mauri we are focussed on reducing our “water intensity” ratio, or the quantity of water used per tonne of final product (excluding by products), over time. We do this through continuously improving our operations and spreading best practice throughout the organisation, aiming to reduce our impact on the local environment and communities. Since 2018, our water intensity has reduced by 30%.

*Defined as m3 of water per tonne of final product excluding by-products. We exclude our 50:50 JVs where we lack operational and financial control.

Waste and circularity

We are committed to reducing waste created as a result of our operations, through a comprehensive strategy focussed on elminate, reduce, re-use and re-cycle.

Reduce Wherever possible we reduce waste by identifying and eliminating unnecessary use of raw materials and packaging, and through continuously improving the efficiency of our operations.

Reuse By replacing single-use packaging items with those we can re-use multiple times and by repairing and re-using where possible, for example with our pallets, we can both reduce waste and reduce the need to purchase new.

In 2024 77% of AB Mauri's total waste was recycled, recovered, reused, or sent for another beneficial use.

Water treatment at AB Mauri’s plant in Bandirma, Türkiye

Recycle For the waste we cannot reduce or reuse, we recycle wherever possible to avoid sending materials to landfill or incineration without energy recovery. This increasingly involves re-purposing materials we previously considered as waste for new uses and markets, for example:

- Biogas from our yeast wastewater treatment processes can be captured and recycled back into our operations, replacing natural gas as a source of heat of electricity generation.

Visit our Energy & Climate Impact page for more information. - Vinasse, also a product of our yeast process, can be used to create fertiliser for agriculture and highly prized ruminant animal feed.

- Husks from our soya milling operation in Royston, UK are sold for processing into animal feed, helping it achieve zero waste to landfill.